Hitachi ZW30, ZW40, ZW50 Wheel Loader Service Repair Manual

The manual is applicable for the Hitachi ZW30, ZW40, ZW50 Wheel Loader Model

Format: PDF

Language: English

Service Manual consists of the following:

For Model ZW30, ZW40, ZW50 as mentioned above:

Service Manual (Troubleshooting) : Vol. No.T4EK-E

Workshop Manual : Vol. No.W4EK-E

Table of Content of the Workshop Manual

SECTION 1 GENERAL

Group 1 Precautions for Disassembling

and Assembling

Group 2 Tightening

Group 3 Painting

SECTION 2 BODY

Group 1 Canopy

Group 2 Cab

Group 3 Counterweight

Group 4 Center Hinge

Group 5 Engine Hood

Group 6 HST Pump and Main Pump

Group 7 HST Motor

Group 8 Control Valve

SECTION 3 TRAVEL SYSTEM

Group 1 Tire

Group 2 Reduction Gear

Group 3 Axle

Group 4 Propeller Shaft

Group 5 Master Cylinder

Group 6 Parking Brake Solenoid

Group 7 Inching Valve

Group 8 Power Steering

Group 9 Steering Cylinder

SECTION 4 FRONT ATTACHMENT

Group 1 Front Attachment

Group 2 Cylinder

Table of Content of the Technical Manual

SECTION 1 GENERAL

Group 1 Specification

Group 2 Component Specification

Group 3 Component Layout

SECTION 2 SYSTEM

Group 1 Fuel System

Group 2 Hydraulic System

Group 3 Electrical System

SECTION 3 COMPONENT OPERATION

Group 1 HST Pump

Group 2 HST Motor

Group 3 Axle

Group 4 Brake

Group 5 Orbitrol

Group 6 Loading Control Valve

Group 7 Main Pump

SECTION 4 OPERATIONAL PERFORMANCE

TEST

Group 1 Introduction

Group 2 Standard

Group 3 Engine Test

Group 4 Wheel Loader Test

SECTION 5 TROUBLESHOOTING

Group 1 Diagnosing Procedure

Group 2 Failure List

Group 3 Engine

Group 4 Vehicle Performance

Group 5 Air Conditioner

Hitachi ZW30, ZW40, ZW50 Wheel Loader Service Repair Manual

Manual guide composition

Hitachi ZAXIS ZW30, ZW40, ZW50 service manual consists of the Technical and the Workshop Manual.

- Information included in the Service Manual: Technical information needed for redelivery and delivery, operation and activation of all devices and systems, operational performance tests, and troubleshooting procedures.

- Information included in the Workshop Manual: Technical information needed for maintenance and repair of the machine, tools and devices needed for maintenance and repair, maintenance standards, and removal / installation and assemble / disassemble procedures.

Travel System and Master Cylinder

Procedures

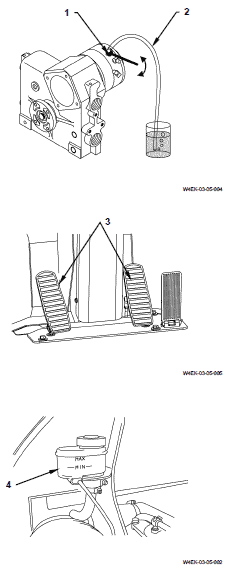

1. Insert transparent vinyl tube (2) to bleeder screw (1).

Put the other one end into the clean container so that brake oil does not spray out.

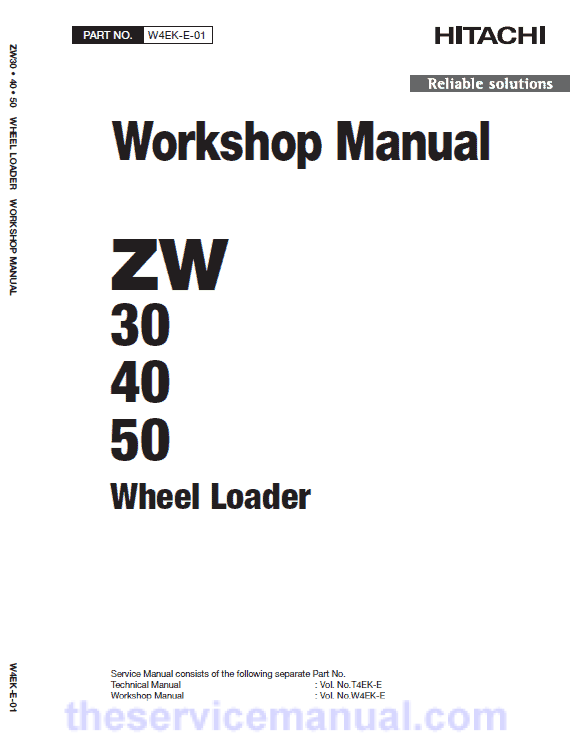

2. Depress the brake pedal (3) several times.

Loosen bleeder screw (1) from half turn to one turn with the pedal depressed.

Drain brake oil and trapped air.

3. Tighten bleeder screw (1).

Release brake pedal (3).

4. Repeat step 2 and step 3 until clean brake oil flows in vinyl hose (2) and bubbles disappear completely.

5. When bubbles completely disappear in the hose, tighten bleeder screw (1) with brake pedal (3) depressed.

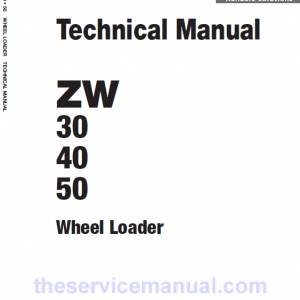

6. After bleeding air, adjust the brake oil level in brake oil tank (4).

When the brake oil level is within MIN to MAX, the amount of brake oil is proper.

Reviews

There are no reviews yet.