Hitachi ZW20 Wheel Loader Service Repair Manual

The manual is applicable for the Hitachi ZW20 Wheel Loader Model

Format: PDF

Language: English

Service Manual consists of the following:

For Model ZW20 as mentioned above:

Service Manual (Troubleshooting) : Vol. No.T4EJ-E-00

Workshop Manual : Vol. No.W4EJ-E-00

Table of Content of the Workshop Manual

SECTION 1 GENERAL

Group 1 Precautions for Disassembling

and Assembling

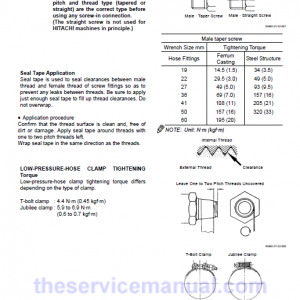

Group 2 Tightening

Group 3 Painting

SECTION 2 BODY

Group 1 Control Valve

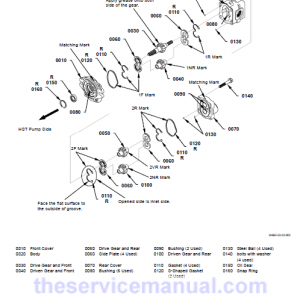

Group 2 Main Pump

SECTION 3 TRAVEL SYSTEM

Group 1 Cab

Group 2 HST Pump

Group 3 HST Motor

Group 4 Reduction Gear

Group 5 Axle

Group 6 Master Cylinder

Group 7 Power Steering

Group 8 Steering Cylinder

SECTION 4 FRONT ATTACHMENT

Group 1 Front Attachment

Group 2 Cylinder

Table of Content of the Technical Manual

SECTION 1 GENERAL

Group 1 Specification

Group 2 Component Specifications

Group 3 Component Layout

SECTION 2 SYSTEM

Group 1 Fuel System

Group 2 Hydraulic System

Group 3 Electrical System

SECTION 3 COMPONENT OPERATION

Group 1 HST Pump

Group 2 HST Motor

Group 3 Axle

Group 4 Brake

Group 5 Orbitroll

Group 6 Control Valve

Group 7 Main Pump

SECTION 4 OPERATIONAL PERFORMANCE TEST

Group 1 Introduction

Group 2 Standard

Group 3 Engine Test

Group 4 Wheel Loader Test

SECTION 5 TROUBLESHOOTING

Group 1 Diagnosing Procedure

Group 2 Failure List

Group 3 Engine

Group 4 Component Layout

Hitachi ZW20 Wheel Loader Service Repair Manual

Manual guide composition

Hitachi ZAXIS ZW20 service manual consists of the Troubleshooting and the Workshop Manual.

- Information included in the Service Manual: Technical information needed for redelivery and delivery, operation and activation of all devices and systems, operational performance tests, and troubleshooting procedures.

- Information included in the Workshop Manual: Technical information needed for maintenance and repair of the machine, tools and devices needed for maintenance and repair, maintenance standards, and removal / installation and assemble / disassemble procedures.

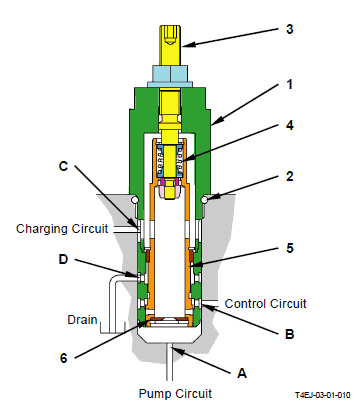

DA Valve

The gear pump is coaxially connected to HST pump for the charge and pilot.

The gear pump flow rate is changed in proportion to the engine speed.

All of flow rate flows to the charge circuit through the orifice of DA valve.

DA valve decreases charge pressure to generate control pressure by using the signal based on the pressure difference caused by the flow rate change between the front and rear of orifice.

Therefore, the pump displacement angle is controlled by pressure almost in proportion to the engine speed.

The charging pump delivery flow rate in proportion to the engine speed flows to charging circuit [C] through port [A].

DA valve decreases charging circuit [C] pressure to generate control pressure in control circuit [B] by using the signals based on the spring force by spring (4) and the pressure difference caused by the flow rate change between the front and rear of orifice (6).

1 – Control Cartridge

2 – O-Ring

3 – Set Screw

4 – Adjust Spring

5 – Differential Piston

6 – Orifice

A- DA Valve Primary side (From Charging Pump) B- DA Valve Secondary side (To Control Circuit) C- DA Valve Secondary side (To Charging Circuit) D- DA Valve Drain

Reviews

There are no reviews yet.