Hitachi ZX75US-5A and ZX85US-5A Excavator Service Repair Manual

The manual is applicable for the ZX800 Hitachi Excavator Model

Format: PDF

Language: English

Service Manual consists of the following:

For Model ZAXIS ZX800 as mentioned above:

Service Manual (Troubleshooting) : Vol. No.TO17VE

Service Manual (Operation) : Vol. No.TT17VE

Workshop Manual : Vol. No.W17VE

Parts Catalog

Circuit Diagram

SI Units (International System of Units) are used in those manual.

Manual guide composition

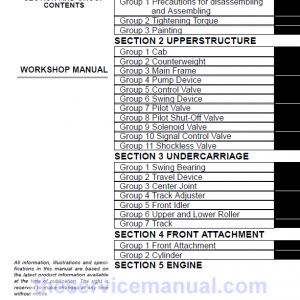

Hitachi ZX800 service manual consists of the Operating, Troubleshooting and the Workshop Manual.

- Information included in the Service Manual: Technical information needed for redelivery and delivery, operation and activation of all devices and systems, operational performance tests, and troubleshooting procedures.

- Information included in the Workshop Manual: Technical information needed for maintenance and repair of the machine, tools and devices needed for maintenance and repair, maintenance standards, and removal / installation and assemble / disassemble procedures.

To avoid injury and damage refer to the service manual and be sure to use appropriate lifting techniques and equipment when lifting heavy parts.

A ZAXIS hallmark industry-leading hydraulic technologies, and performance no other can beat. New ZAXIS provides reliable solutions: impressive fuel economy, swift front movements, and easy operation. You’ll also find Hitachi technological prowess and expertise, such as the optimized hydraulic system and engine.New ZAXIS features the key benefits of high quality, low fuel consumption, and high durability, all of which serve to ensure low running costs.New ZAXIS, which is empowered by comprehensive evolution, will realize customers visions and dreams, and pioneer your colorful future

Hydraulic System Main Circuit Extract Outline

• Main pumps (1 and 2) draw hydraulic oil from the hydraulic oil tank. Main pump 1 and main pump 2 deliver pressure oil to the 4-spool control valve and the 5-spool control valve respectively.

• Delivered pressure oil is routed to the motor(s) or cylinder(s) in response to operation(s) of the spool(s) in the control valve(s).

• The return oil from the motor(s) and/or cylinder(s) flows back to the hydraulic oil tank via the control valve and/or the oil cooler.

• When the oil temperature is low (high viscosity), the oil flow resistance increases in the oil cooler, which opens the bypass check valve, allowing hydraulic oil to return directly to the hydraulic oil tank without passing through the oil cooler.

Reviews

There are no reviews yet.